Baosi BSC SRV300B Single-stage rotary vane vacuum pump Features

The Baosi SRV300B is a high-performance oil rotary vane vacuum pump. It is designed to provide reliable and efficient operation in various industrial applications.

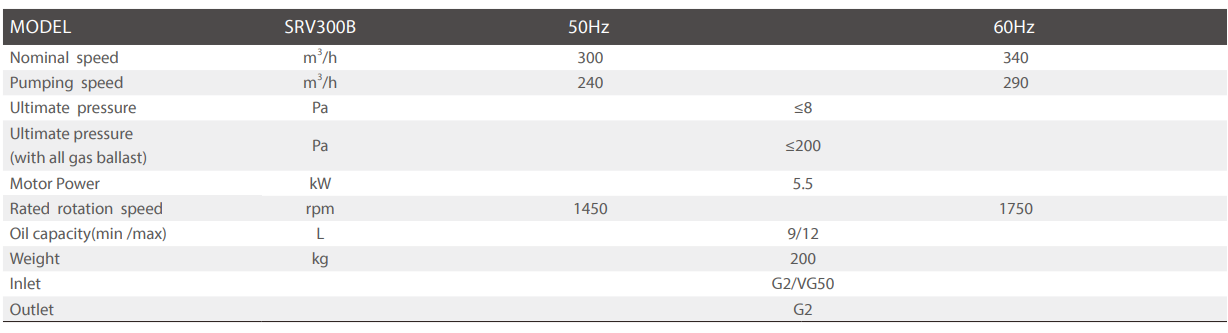

Key Specifications

Pumping Speed: The SRV300B has a pumping speed of 630 m3/h at 50Hz and 550 m3/h at 60Hz[1].

Ultimate Pressure: The ultimate pressure of the SRV300B is ≤ 5 x10^-1 Pa when measured with a Pirani vacuum gauge and using Baosi's special vacuum pump oil BSO-68[1].

Motor Power: The motor power for a 380V (three-phase) operation is 0.4 kW (4 poles) and 0.55 kW (4 poles). For a 220V (single-phase) operation, the motor power is not specified[1].

Oil Requirement: The SRV300B requires 0.7 liters of oil for operation[1].

Inlet and Outlet: The inlet port is DN KF25 (with an optional KF16), and the outlet port is DN KF25[1].

Noise Level: The noise level of the SRV300B is 63 dB when the gas town is closed and 65 dB when it is open[1].

Weight: The weight of the SRV300B is 22.5 kg for a three-phase operation[1].

Additional Features

The SRV300B is designed with a focus on performance and longevity. To avoid affecting the pump's performance and lifespan, it is recommended to use Baosi's special vacuum pump oil[1]. This oil has been specifically designed to work with Baosi vacuum pumps, ensuring optimal performance and longevity.

The SRV300B also features a robust design that can withstand demanding industrial environments. Its compact size and relatively low weight make it easy to install and integrate into various systems.

In conclusion, the Baosi SRV300B is a reliable and efficient vacuum pump that offers high performance and durability for a wide range of industrial applications. Its key features and specifications make it a versatile choice for those in need of a high-quality vacuum pump.

The use of non-spring rotary vane to achieve low noise, low vibration and long service life.

Built-in oil check valve is used to reduce the oil return phenomenon.

Built-in forced fed oil pump is used to ensure the long-term continous operation of the pump at atmospheric pressure.

The use of air cooling, oil cooling, water cooling and other cooling methods to ensure the good cooling effect, and make the long-term stable runnig of the pump as well as the stable pumping performance.

- Reasonable structure has the advantages of easy assembly and disassembly, as well as the fast and easy maintenance.

CE cerficate

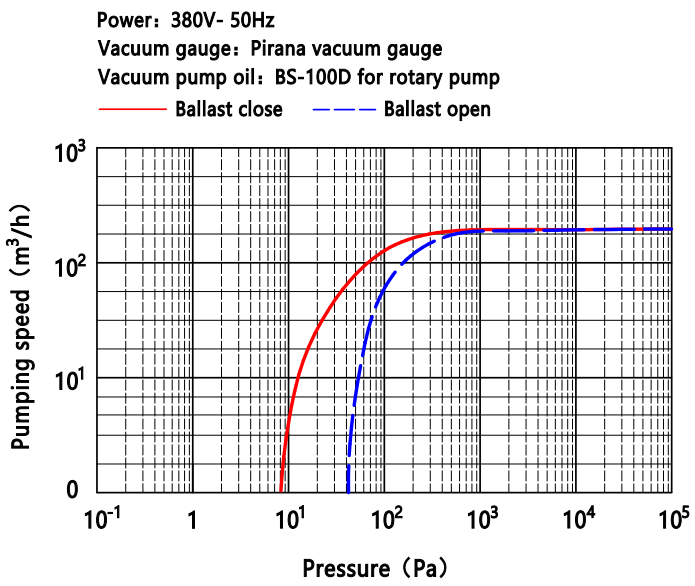

Baosi BSC SRV300B Single-stage rotary vane vacuum pump Performance